Superior Tech

Supreme Quality

Precision. Innovation. Performance. Redon's advanced milling technologies redefine what's possible, offering flexible solutions for every stage of your milling workflow.

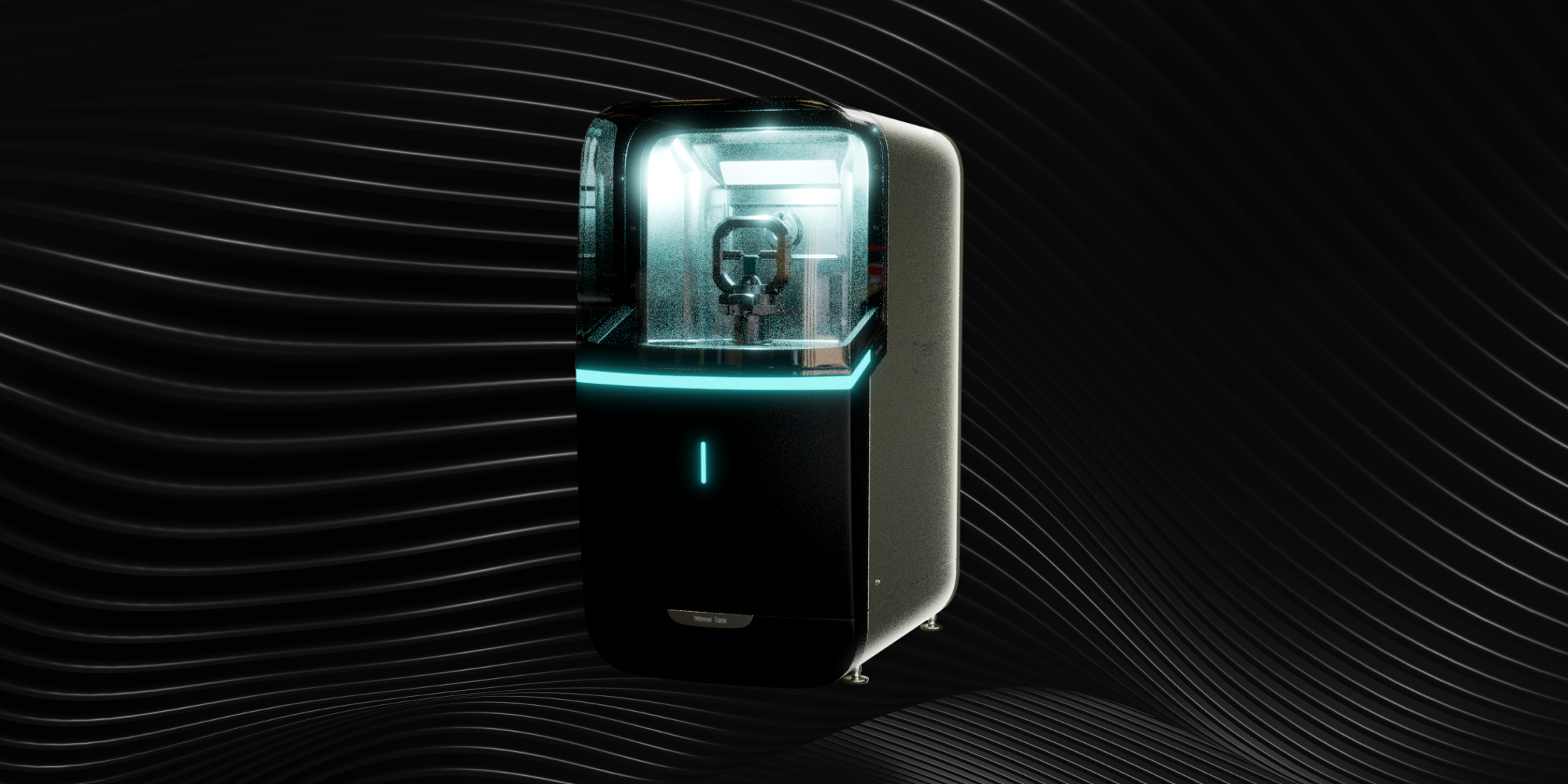

The R-One+ is designed for clinics focused on delivering fast, high-quality restorations directly at the chairside for an exceptional patient experience.

The Redon R-One+ provides chairside milling, 7-bur capacity, and fast in-clinic production with a multi-material compatibility.

The Best Mill is ideal for labs requiring versatile, high-output milling across a wide range of materials, enabling maximum productivity with dual wet/dry capabilities.

The Redon Best Mill provides five-axis milling, 24-bur capacity, automatic block changer and dual wet/dry capabilities for precision across all dental materials.

The Redon Hybrid is perfect for labs needing adaptable, multi-material capabilities for complex restorations across both wet and dry workflows.

The Redon Hybrid offers wet/dry options and 1-micron accuracy with a 12-tool automatic changer and 5-axis milling.

The Redon GTR is built for labs that demand top-tier power, accuracy, and flexibility, especially for challenging, high-precision restorations.

The Redon GTR combines extreme angle precision, five-axis simultaneous milling,Twin Tool Technology, and 3.7 kW spindle power for complex restorations in any material.

Engineered for Power,

Designed for Precision

Increase revenue with single-visit restorations, thanks to R-One+'s fast, efficient chairside milling.

Your Practice, Reimagined

Plug N' Play

Plug N' Play

Start producing from day one. With an integrated water tank, compressor, and filtration system, the R-One eliminates the need for additional setup, saving both space and time.

Four-Axis

Four-Axis

Engineered for complex restorations, the R-One's high-performance spindle and four-axis milling ensure detailed, precise results across materials.

6 Blocks

6 Blocks

Designed for high-volume work, the R-One's multi-block holder accommodates up to six glass ceramic blocks, allowing simultaneous milling. Ideal for busy labs aiming to maximize productivity and output.

7-Bur Changer

7-Bur Changer

With an automatic tool changer and 7-bur magazine, the R-One offers uninterrupted milling for efficient single-tooth restorations.

Engineered for Power,

Designed for Precision

Maximize output and cut costs with Best Mill's 15-block changer and high-speed, dual-function milling.

Your Practice, Reimagined

Wet & Dry

Wet & Dry

This dual functionality reduces costs and boosts efficiency for versatile dental applications.

60,000 RPM

60,000 RPM

This high-speed capability enables efficient processing across various materials without compromising on detail.

24-Bur Capacity

24-Bur Capacity

The high-capacity tool magazine ensures continuous milling without manual interventions, maximizing productivity.

Five-Axis

Five-Axis

Its wide machining angle makes it ideal for intricate surfaces, delivering precision across all dental materials.

Engineered for Power,

Designed for Precision

Grow your lab's capabilities with Hybrid's multi-material milling and seamless wet/dry switching.

Your Practice, Reimagined

Wet & Dry

Wet & Dry

With both dry and wet milling options, the Redon Hybrid effortlessly handles a range of materials. From zirconium to wax and glass-ceramic, this machine is equipped to manage every dental application in your lab.

5-Axis

5-Axis

Built with 5-axis simultaneous milling, the Hybrid delivers ultra-precise results, ensuring flawless detail on every restoration. It's ideal for intricate designs that demand accuracy and smooth surfaces.

12-Tool Changer

12-Tool Changer

The Redon Hybrid's 12-tool automatic changer with tool fracture control allows uninterrupted milling for complex restorations. This high-capacity system optimizes productivity, minimizing downtime and manual intervention.

1μm

1μm

Achieve fast, dependable results with the Hybrid's precision tool sensor, designed for accuracy within 1 micron. This high-speed setup enhances efficiency across various materials, ensuring consistency and quality in every job.

Engineered for Power,

Designed for Precision

Tackle high-value, complex cases profitably with GTR's powerful spindle and extreme angle milling.

Your Practice, Reimagined

-30° to +120°

-30° to +120°

Designed for versatility, the Redon GTR achieves a wide milling angle range, from -30° to +120°, making it perfect for challenging designs and advanced restorations. This capability allows for unprecedented flexibility across materials.

3.7 kW

3.7 kW

The GTR's 3.7 kW spindle delivers unmatched speed and power, reaching up to 60,000 RPM for detailed milling. This combination of speed and strength ensures consistent, high-quality results across all material types, from titanium to glass-ceramic.

12-Tool Changer

12-Tool Changer

Equipped with Twin Tool Technology and a 12-tool automatic changer, the GTR provides smooth, uninterrupted milling with precision down to 1 micron. This setup maximizes productivity, minimizing downtime while keeping accuracy at its peak.

5-Axis

5-Axis

Accurate Multi-Axis Milling Built with 5-axis simultaneous milling technology, the GTR delivers flawless results with advanced tool path control. It's ideal for complex dental restorations that require precise, multi-angle processing and high-quality surface finishes.

Precision milling optimized for,

glass-ceramic and premills.

Experience seamless versatility with the R-One+ as it mills PMMA, glass-ceramic, zirconium, composite, wax, and PEEK with chairside speed and precision.

Zircronium

Redon's high-speed, high-torque milling ensures flawless results in zirconium, delivering detailed, durable restorations with a natural finish.

Glass-Ceramic

odor amet, consectetuer adipiscing elit. Vulputate interdum sagittis mus cubilia ridiculus proin. Integer odio congue ligula laoreet habitant lacinia habitasse parturient.

Premill

odor amet, consectetuer adipiscing elit. Vulputate interdum sagittis mus cubilia ridiculus proin. Integer odio congue ligula laoreet habitant lacinia habitasse parturient.

Wax

With ultra-fine milling capabilities, Redon machines handle wax effortlessly, creating sharp, accurate patterns for trial restorations and casting models.

Versatile precision milling for

all materials.

Maximize lab efficiency with Redon Best Mill, designed for precision across zirconium, CoCr, glass-ceramic, PMMA, wax, and titanium with dual-function wet and dry milling.

Titanium

Redon's robust milling technology tackles titanium's strength, producing precise, biocompatible implant components with ease.

Wax

With ultra-fine milling capabilities, Redon machines handle wax effortlessly, creating sharp, accurate patterns for trial restorations and casting models.

Zircronium

Redon's high-speed, high-torque milling ensures flawless results in zirconium, delivering detailed, durable restorations with a natural finish.

CoCr

Redon machines maintain high precision and control with CoCr, making it ideal for durable, complex frameworks that require strong, corrosion-resistant materials.

Glass-Ceramic

Redon systems handle glass-ceramic delicately yet efficiently, ensuring lifelike translucency and detail for highly aesthetic restorations.

Premill

Redon's precision ensures efficient, accurate milling of premill blanks, allowing for quick, custom adjustments tailored to patient cases.

Versatile precision milling for

all materials.

Handle diverse restorations effortlessly with Redon Hybrid, built to mill glass-ceramic, zirconium, titanium, PMMA, composite, and wax with precision and flexibility.

Titanium

Redon's robust milling technology tackles titanium's strength, producing precise, biocompatible implant components with ease.

Wax

With ultra-fine milling capabilities, Redon machines handle wax effortlessly, creating sharp, accurate patterns for trial restorations and casting models.

Zircronium

Redon's high-speed, high-torque milling ensures flawless results in zirconium, delivering detailed, durable restorations with a natural finish.

CoCr

Redon machines maintain high precision and control with CoCr, making it ideal for durable, complex frameworks that require strong, corrosion-resistant materials.

Glass-Ceramic

Redon systems handle glass-ceramic delicately yet efficiently, ensuring lifelike translucency and detail for highly aesthetic restorations.

Premill

Redon's precision ensures efficient, accurate milling of premill blanks, allowing for quick, custom adjustments tailored to patient cases.

Versatile precision milling for

all materials.

Redon GTR masters challenging materials, milling titanium, zirconium, CoCr, glass-ceramic, wax, and PMMA with power and extreme angle precision.

Titanium

Redon's robust milling technology tackles titanium's strength, producing precise, biocompatible implant components with ease.

Wax

With ultra-fine milling capabilities, Redon machines handle wax effortlessly, creating sharp, accurate patterns for trial restorations and casting models.

Zircronium

Redon's high-speed, high-torque milling ensures flawless results in zirconium, delivering detailed, durable restorations with a natural finish.

CoCr

Redon machines maintain high precision and control with CoCr, making it ideal for durable, complex frameworks that require strong, corrosion-resistant materials.

Glass-Ceramic

Redon systems handle glass-ceramic delicately yet efficiently, ensuring lifelike translucency and detail for highly aesthetic restorations.

PMMA

Redon machines process PMMA smoothly, achieving consistent, precise contours ideal for temporary restorations and aesthetic prototypes.

Does the R-One+ support chairside milling?

Yes, R-One+ is optimized for chairside production, allowing patients to receive fast, single-visit restorations.

How many tools can the R-One+ hold?

The R-One+ includes a 7-bur automatic tool changer, supporting uninterrupted milling and efficient workflow.

Is R-One+ compatible with other dental software?

Yes, R-One+ integrates seamlessly with all oral scanners and CAM software, making it a flexible choice.

How does R-One+ handle multiple blocks?

The R-One+ has a multi-block holder that can accommodate up to six blocks, enabling simultaneous milling of multiple units.

Does R-One+ require additional units to operate?

No, the R-One+ is all-in-one with a built-in water tank, compressor, and filtration system, so it's ready to use without extra units.

What spindle speed does R-One+ offer?

The R-One+ spindle reaches high speeds for fast and accurate milling, especially useful for complex restorations.

Redon R-One+, the answer to all your milling needs

R One+ Essential Information.

Discover detailed responses to common questions about the R-One+ and how it fits seamlessly into your clinical workflow.

What materials can Best Mill handle?

Best Mill processes zirconium, CoCr, glass-ceramic, PMMA, and wax, making it ideal for diverse dental applications.

How many tools can Best Mill hold?

Best Mill's 24-bur capacity supports continuous milling with automatic tool changes.

Is Best Mill suitable for intricate restorations?

Yes, the 5-axis milling technology allows Best Mill to handle complex restorations with high precision.

What's the body structure of Best Mill?

It's built with a monoblock cast body, reducing vibration and enhancing stability for accurate results.

Does Best Mill integrate with open CAM software?

Yes, it's compatible with open system CAM software, allowing seamless integration with existing lab workflows.

Is Best Mill suitable for intricate restorations?

Yes, the 5-axis milling technology allows Best Mill to handle complex restorations with high precision.

Redon Best Mill, the ultimate solution for precision and versatility.

Best Mill Essential Information.

Discover detailed responses to common questions about the Best Mill and how it fits seamlessly into your clinical workflow.

Can Hybrid handle both wet and dry milling?

Yes, Hybrid supports both wet and dry milling, ideal for labs needing flexible production.

What is Hybrid's accuracy level?

With 1-micron precision, Hybrid achieves high-quality results on intricate restorations.

What spindle power does Hybrid offer?

The 1.2 kW spindle allows fast, precise milling across a range of materials.

Does Hybrid have automatic tool changing?

Yes, the 12-tool automatic changer ensures smooth transitions for efficient, continuous production.

Can Hybrid be used with open CAM software?

Yes, it's compatible with open systems, integrating smoothly into existing workflows.

Is Hybrid made to reduce vibration?

Yes, its monoblock cast body structure enhances stability and minimizes vibration.

One machine, every material. Redon Hybrid, difference.

Hybrid Essential Information.

Discover detailed responses to common questions about the Hybrid and how it fits seamlessly into your clinical workflow.

Does GTR support wet and dry milling?

Yes, it's designed for both dry and wet milling to maximize material compatibility.

What's the max angle range for GTR?

The GTR can mill at extreme angles from -30° to +120°, suitable for complex and advanced restorations.

How powerful is the GTR's spindle?

Its 3.7 kW spindle reaches up to 60,000 RPM, delivering both speed and power for detailed results.

How many tools does GTR hold?

GTR has a 12-tool automatic changer, which supports uninterrupted, high-efficiency milling.

Does GTR include Twin Tool Technology?

Yes, Twin Tool Technology in the GTR provides a reliable, seamless workflow with minimal downtime.

Is GTR suitable for intricate restorations?

Yes, with 5-axis milling and advanced tool path control, GTR achieves precision on complex restorations.

Redon GTR, power, precision, versatility redefined.

GTR Essential Information.

Discover detailed responses to common questions about the GTR and how it fits seamlessly into your clinical workflow.